UV Laser Marking Machine adopts JPT UV Laser source, the third-order cavity frequency doubling technology, compared with infrared laser, UV lasers at 355nm provide a small-size spot and a big focal depth, short laser wavelength interrupts molecular chains of material, can greatly reduces the mechanical deformation and temperature distortion of materials, it is a cold laser, mainly used for super precise marking and engraving, particularly suitable for food, pharmaceutical packaging material marking, micro porous, high-speed dividing for glass, complex graphics wafer cutting on silicon materials, etc. UV laser is an ultraviolet laser beam which generated after the high-power multimode diode pumped laser and then frequency doubling again, and mark through computer-controlled high-speed scanning galvanometer deflection to change the path of laser beam automatically.

0086-150-1350-9330

Feature

1. High-quality laser beam, small-size spot, can do super precise marking & engraving.

2. Perfect marking performance:

(1) Short UV wavelength 355nm reduces heat effect on work piece;

(2) Precise marking effect and available repeatable marking;

(3) High precision scanning galvanometer laser head;

(4) Extraordinary fine spot guarantees perfect marking performance;

(5) Non-contact marking.Permanent mark.

3. Heat affected area is very small, no heating effect, material will not be burned or deformed.

4. High marking speed, high efficiency, stable performance, small size, low power consumption.

5. Very suitable for the material which is greatly reacted by thermal radiation, can work with production line to feed and discharge materials automatically.

Application

1. UV Laser Marking Machine is mainly used in precision processing of high-end market, handicrafts, medicine,

cosmetics, video and other polymer materials packaging bottle, the mark is very precise and stands wear, better

than ink printing and pollution-free.

2. The flexible PCB marking and scribing, silicon and wafer micro hole, blind hole processing;

3. LCD glass QR code marking, glass wares punching, metal surface coating marking, plastic buttons, communications

equipment, gifts and so on.

5. Very suitable for the material which is greatly reacted by thermal radiation, can work with production line to feed and discharge materials automatically.

Technical Parameters

| Model | MY-LM | ||||||||||

| Laser Power | 3W | ||||||||||

| Optional Laser Power | 3W /5W | ||||||||||

| Laser Wavelength | 355nm | ||||||||||

| Working Area | 100*100mm | ||||||||||

| Optional Working Area | 70*70mm / 140*140mm / 200*200mm | ||||||||||

| Beam Quality | M2 <1.2 | ||||||||||

| Output Laser Power | 0~100% adjustable | ||||||||||

| Output Frequency | 20~150KHz adjustable | ||||||||||

| Power Stability (8h) | <±1%rms | ||||||||||

| Pulse Width | 10-50ns | ||||||||||

| Focus Spot Diameter | <0.01mm | ||||||||||

| UV Laser Source | JPT | ||||||||||

| Scan Head |

Galvo-Tech / WISE SCAN from China |

||||||||||

| Controller and Software | JZC Controller & EzCAD2 Software (Optionlal: EzCAD3 /SAMLight /LightBurn) | ||||||||||

| Marking Speed | 7000mm/s | ||||||||||

| Min. Line Width | ≤0.005mm | ||||||||||

| Min. Character | 0.15mm | ||||||||||

| Repeated Precision | ±0.003mm | ||||||||||

| Compatible Format of File | PLT, DXF, AI, BMP, JPG and so on. | ||||||||||

| System Operation Environment | Windows XP / 7 / 8 / 10 / 11 - 32 / 64bits | ||||||||||

| Cooling Mode | Air Cooling /Water Cooling | ||||||||||

| Operation Environment | 0℃~40℃ | ||||||||||

| Lifespan of UV Laser Source | Max. 20,000 hours | ||||||||||

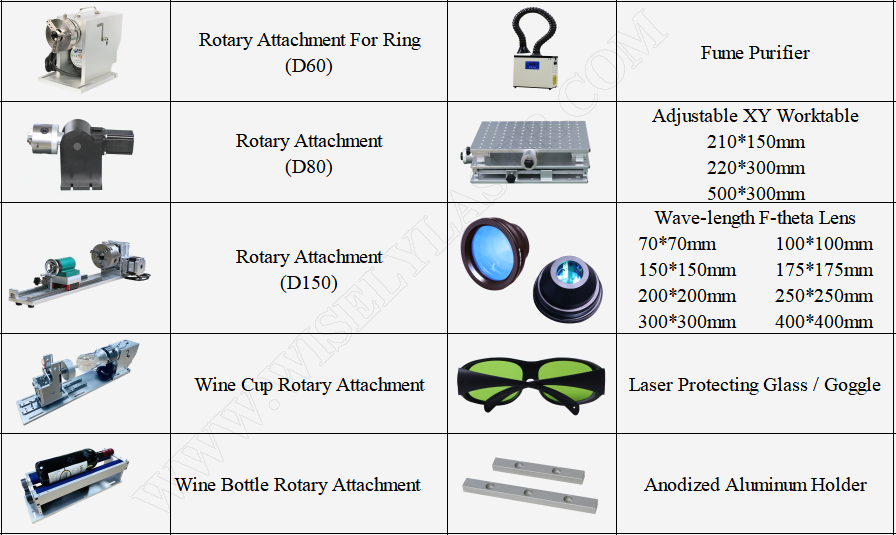

Optional Devices

payment

100% or 40% prepaird before production, balance payment before shipment. (Negotiable)

Bank Wire, Paypal, Western Union, Credit Card, Alibaba.

Shipment

Machine will be sent out 5-10 working days after receiving the payment.

By Express: 6-10 days. (Highly Recommended)

By Sea: 30-45 days.

Packaging

International standard plywooden case.

Warranty

Whole machine has a warranty period of 12 months since the production date.

Training

1~3 working days training free of charge in factory or online training via TeamViewer, Skype, WeChat, FB